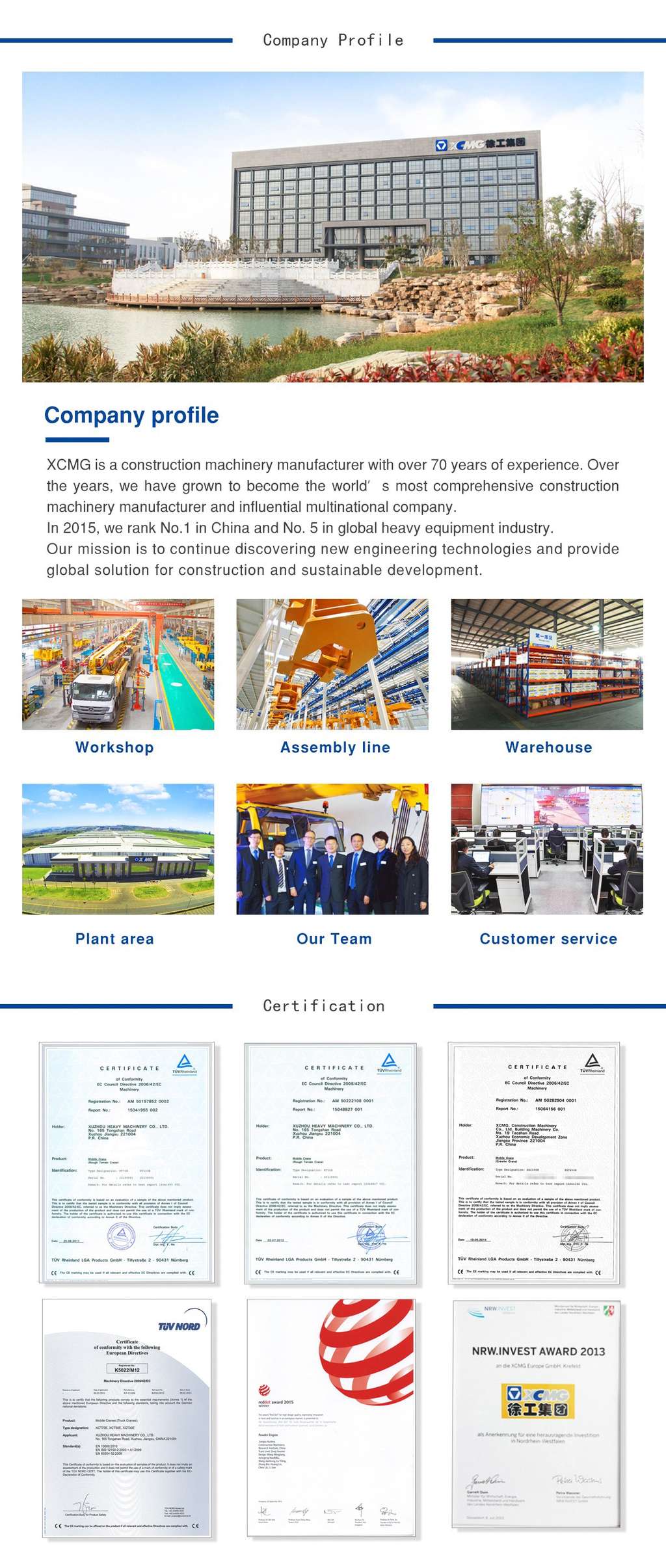

XCMG Official Manufacturer TZ3A Three-boom hydraulic pilot drill jambo

Description

Recommendation

TZ3A Three-Boom Hydraulic Pilot Drill Jambo

TZ3A Three-Boom Hydraulic Pilot Drill Jambo

1、Main Applications

It’s mainly applicable for the tunneling operations of roadways and tunnels in mines and other underground projects.

Capable of drilling of blast holes, anchor rod holes, and undermining holes and installation of explosives, anchor rods, and air ducts.

Maximum operation area coverage: 180㎡.

2、Technical Features

(1)Drill Jambo

The hydraulic drill jambo adopts special structural process on the basis of the domestic tunneling process to realize super-strong anti-bending capability, high drilling speed, and low drilling tool consumption and effectively improve the working performance of tunnel side hole drilling.

(2)Propeller

The lightweight high-strength alloy girder features high anti-bending, anti-distortion, and anti-fatigue performances and longer life.

(3)Chassis

It’s applied with energy-saving, environmental-friendly, and low emission engine, powerful all-road all-drive self-adaptive traveling system, integral frame, and rear-wheel steering system, featuring high vehicle stability.

(4)Drill Boom

The all-directional paralleling-maintained drill booms of proprietary technology features accurate positioning. The drill booms adopt equal-strength structure design to realize reasonable structure, high strength, and long life.

(5)Drilling System

The automatic anti-seizure, anti-empty-drilling, and automatic return functions of drilling tool are provided to effectively improve the drilling efficiency.

3、TZ3A drill jambo (Optional version)

(1)Highlights of FGS system

a. Customized navigation process

b. Visual display of all boom positions

c. Click to zoom up every display

d. Automatic stop of drilling upon sending of 24V signal to every drilling boom

e. Press reset button to automatically stop drilling in event of interference.

f. Production report after every drilling cycle

g. Calculation recommendation for charge volume

h. Optional top view and side view

i. 3D views in drilling data management for the viewing of background office

j. Display of drilling pressure of Montabert jack drill and indication of overpressure

k. Available Chinese operation interface

l. 4 pressure sensors on every boom

m. Synchronized data among all display screens in cab

n. USB synchronized production data

(2)Advantages of FGS system

a. Rapid positioning and simplified process of booms

b. Easy operation interface

c. Automatic return of jack drill and level bottom end of blast holes

e. Management of hole arrangement diagram

f. Production management (Blast hole drilling effect)

g. Really firm components

|

Item |

Unit |

Parameter |

|

Maximum operation cover area |

㎡ |

180 |

|

Maximum operation height |

mm |

13075 |

|

Maximum operation width |

mm |

15725 |

|

Drill boom extended length |

mm |

1600 |

|

Drill boom lifting angle |

° |

65/-30 |

|

Tit angle for propeller |

° |

±45 |

|

Propeller tit angle |

° |

360 |

|

Propeller compensation length |

mm |

1800 |

|

Maximum propulsive force |

kN |

20 |

|

Drill hole depth |

mm |

5140 |

|

Impact power of gadder |

kW |

18.8 |

|

Impact frequency of gadder |

Hz |

40-50 |

|

Swing torque of gadder |

N.m |

780 |

|

Diameter for dill hole |

mm |

φ43-φ102 |

|

Water flushing pressure |

bar |

10-15 |

|

Gas lubrication pressure |

bar |

2-4 |

|

Lifting height for working service platform |

mm |

12000 |

|

Swing width for working service platform |

mm |

15500 |

|

Rated load for working service platform |

kg |

400 |

|

Lifting height of cab |

mm |

1200 |

|

Lifting height of cab roof |

mm |

700 |

|

Total installed power |

kW |

200 |

|

External power supply |

V/Hz |

380/50 |

|

Maximum traveling speed |

km/h |

15 |

|

Maximum gradability |

° |

15 |

|

Engine power |

kW |

200 |

|

Transport dimension |

mm |

16000*2950*3400 |

|

Curb weight |

kg |

45800 |

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall