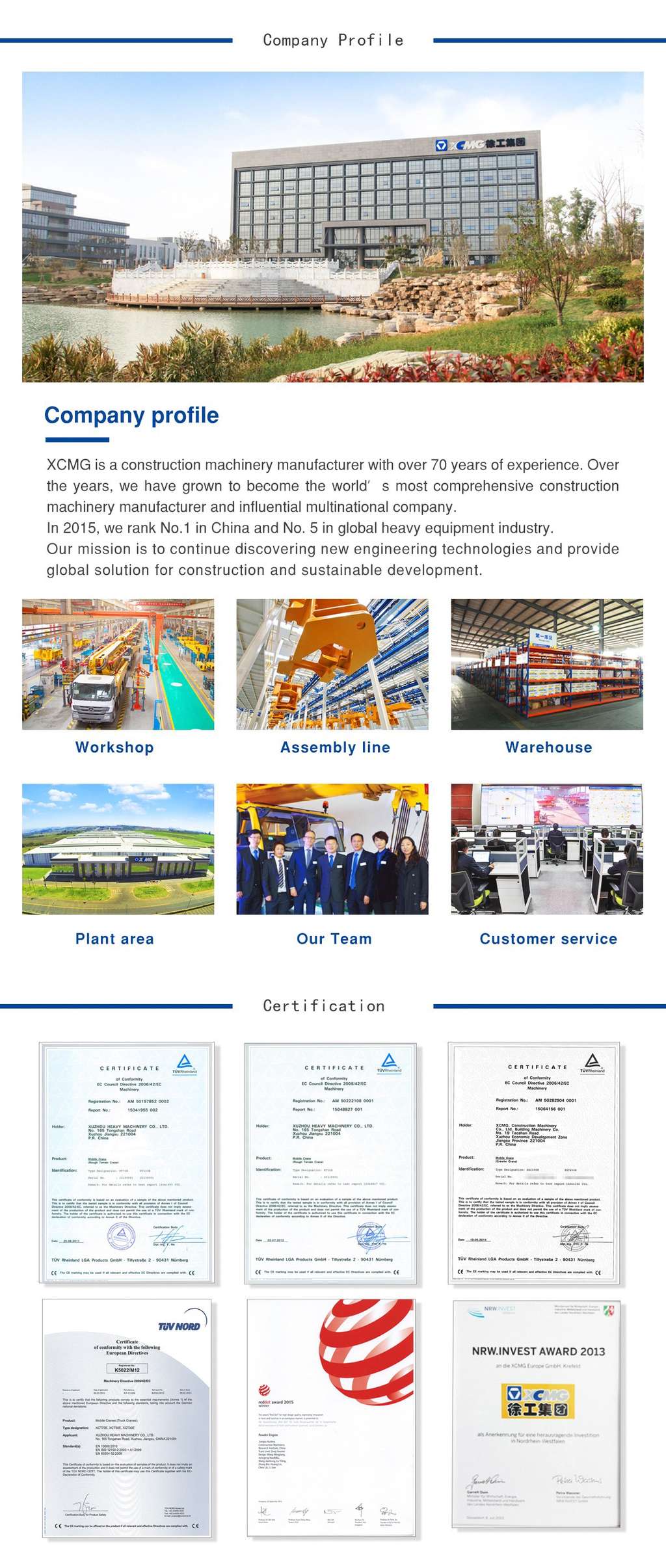

XCMG Official Manufacturer 5 tons Compressed Garbage truck XZJ5120ZYSD5 for sale

Description

Recommendation

XZJ5120ZYSD5 Compressed Garbage Truck

XZJ5120ZYSD5 Compressed Garbage Truck

1) Its technological advancement andleading level is guaranteed according to related national, industrial andenterprise standards. The vehicle body is in a streamline, increasing itsmovement and beauty. The entire truck is in a streamlined design. It isbeautiful, environmentally-friendly and coordinative with the culturalenvironment in modern city. The product is advanced, beautiful, safe andreliable, with top-ranking quality in China.

2) Two-way compression technology isadopted. Optimized hydraulic system and advanced press fitting structuraldesign (for instance, the oil cylinder and the motional orbit of the slidingplate are on the same plane, making sure that the compressing force is just theacting force of the oil cylinder instead of the component force of oil cylinderacting force) result in large compressing force and large compression ratio ofpress fitting. Besides, the simulation design of garbage packing direction(hook face) with push plate also guarantees that garbage with differentcomponents can be evenly compressed and that the entire truck can be fullyfilled without dead angle and gap or blocking, which remarkably improves thenet loading capacity of garbage. Under the same volume, its garbage loadingcapacity is approximately 20% larger than that of similar products in China.

3) The slideway structure of push plateis of groove type pathway on both sides. Compared with the pathway on the baseplate of the truck bed, it has the following advantages: large rigidity ofpathway, good stability, zero deformation of base plate, stable movement ofpush plate, complete unloading of garbage and reliable operation.

4) High-strength climate-resistant steelis adopted for the base plate of truck bed and refuse hopper. Profile steel isdesigned for the entire truck. It is featured by light weight, large garbageloading capacity and oil saving, making sure zero deformation and good economicefficiency of the truck.

5) Compared with the constant high-pressuresystem generally used in China, the optimally designed medium-pressurepressure-variable hydraulic system has such advantages as quick dynamicresponse, small internal thermal loss, high work efficiency, short cycling timeand simple operation, especially for reliable operation and low failure rate.

6) The design of central sewage conduitprevents sewage leakage. The integrated design of hopper and sewage tank givesa radical solution to such secondary pollution issues as dropping, leaking andbubbling, and thus absolutely avoids secondary pollution of the garbage truckin the process of compressive loading and transportation.

7) Movement of the nylon plate of thesliding plate in the slideway is realized by four groups of importedhigh-density macromolecular PE guide support slippers. Compared with thebearing steel and other rigid slippers universally adopted in China, it reducesthe sliding resistance and wear of the kinematic pair. Compared with domesticplastic sliding blocks adopted in the same industry, the high-densitymacromolecular PE sliding block is endurable and wear-proof. It is basicallyunnecessary for replacement under normal maintenance.

8) The sliding plate is of a guide railidler wheel structure. The guide plate is of reverse design and nylon guiding.It is flexible for garbage scraping.

9) A garbage reflux preventive device isprovided. Sufficient space is guaranteed for the hopper by isolating with abaffle plate. Thus, efficient operation is realized.

10) When the loader is lifted, thescraper blade may clean the garbage for a second time, making sure no residualgarbage during laying-off.

11) A cab operating system is provided aswell. The driver can operate in the cab to lift the loader and unload garbagethrough the push plate.

12) An electrically-controlledaccelerator is installed for automatic acceleration and constant speed. Theelectronic accelerator guarantees the optimal coordination between thehydraulic oil pump and the engine speed.

13) A liaison buzzer is arranged on bothsides of the tail gate and in the driving cab. The operator and the driver cankeep contact through it. Moreover, the tail gate is also equipped with aloading button for “emergency stop of device” for timely stop. If the tail gatemust be lowered in case of inspection, overhaul and cleaning, the safety rodshall be erected to effectively present the tail gate from falling downsuddenly. Multiple safety protection devices guarantee the operation safety.

|

MODEL |

XZJ5120ZYSD5 |

||

|

Specification |

Chassis Model |

DFL1120B21 |

|

|

Vehicle Model |

5t |

||

|

L.W.H |

7510×2470

×2990mm(no feeding device) 7860×2470

×2990mm(tipping bucket) 7610×2470

×2990mm(bucket shape) 7900×2470×2990mm (Swing arm) |

||

|

Weight |

Total Weight |

12495kg |

|

|

Curb Weight |

7930kg (no feeding

device) 8600kg (tipping

bucket) 8600kg (bucket shape) 8600kg (Swing arm) |

||

|

Rated Payload |

4370kg (no feeding

device) 3700kg (tipping

bucket) 3700kg (bucket shape) 3700kg (Swing arm) |

||

|

Fitted parts specifications |

The Volume of Carriage |

10m3 |

|

|

Carriage |

Length |

3660mm |

|

|

Width |

2150mm |

||

|

Height |

1645mm |

||

|

Feeding port |

Height from the ground |

1040mm |

|

|

Width |

1680mm |

||

|

Fill Capacity |

1.75m3 |

||

|

Drain tank volume |

350L |

||

|

loading cycle time |

16~18s |

||

|

The loading Angle of the loader |

~95° |

||

|

Hydraulic system rated pressure |

19.6MPa |

||

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall