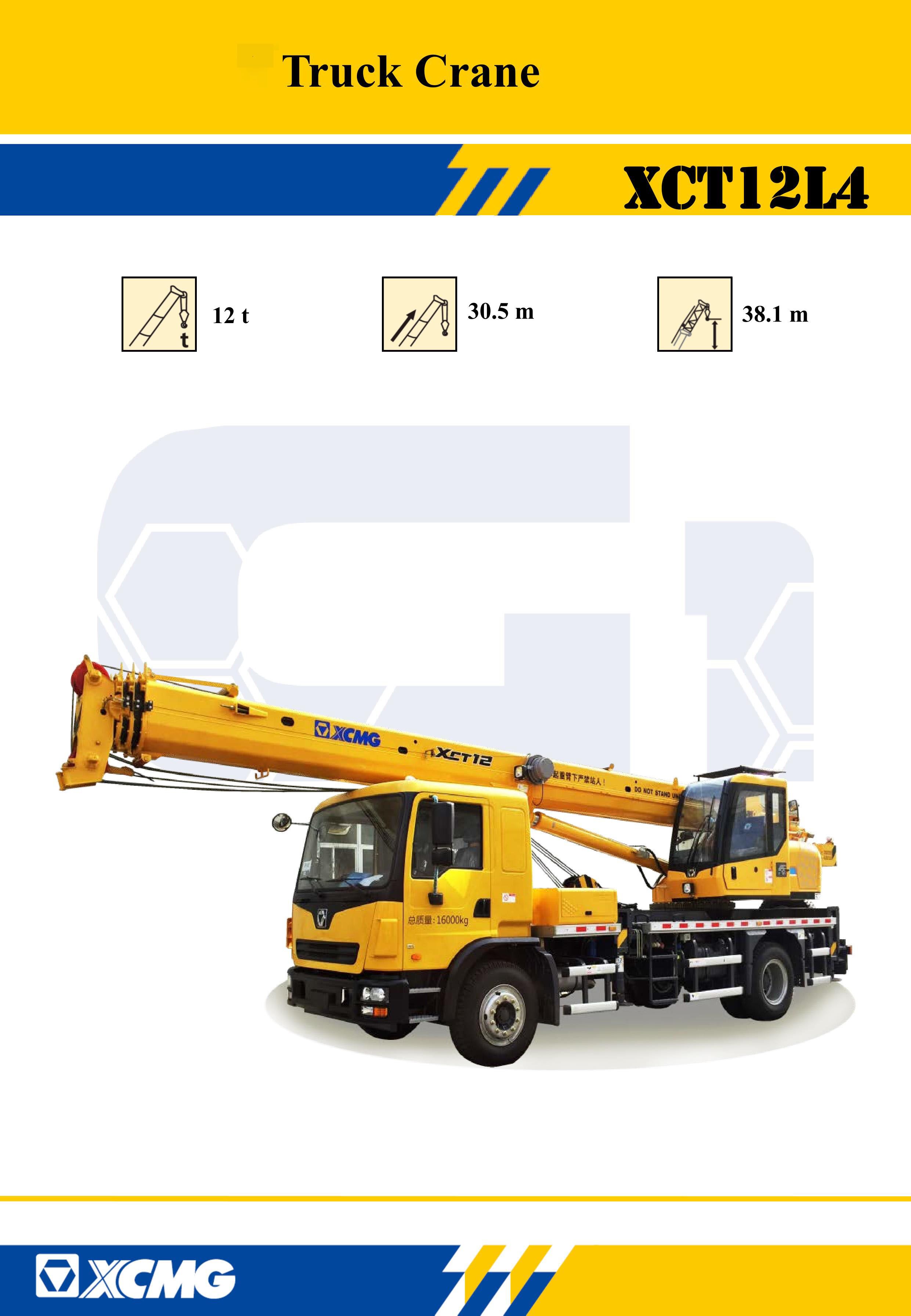

XCMG Official XCT12L4 Truck Crane for sale

Description

Recommendation

|

Technical specifications |

||||

|

Chassis |

|

Superstructure |

||

|

Frame |

Designed and manufactured by XCMG, with all covered walking surface, anti-torsion box structure, made of imported high strength steel. |

Frame |

Designed and manufactured by XCMG; Full- covered walking platform, made of high-strength steel |

|

|

Outrigger |

4 outriggers, H-shaped arrangement, lateral and vertical outrigger controlled by the hydr-aulic control. Both sides of the chassis equip-ed with electronic control console, the console installed with luminous level, lighting and speed buttons; outrigger cylinders equipped with one-way valve, and the vertical outrigger has two-way hydraulic lock. Float...(p350mmOutrigger reaction force at max. lifting capacity... 189KN |

Hydraulic system |

Variable pump driven by chassis engine, used for hoisting, elevating, telescoping and slewing operation. Imported electro-hydraulic direction valve, matching perfectly stably. Air-cooled hydraulic oil cooler, which may effectively reduce the temperature of oil in the system, suction filter and return filter. |

|

|

Engine |

WP6.220E50, in-line six-cylinder water-cooled EFI diesel engine, manufactured by Daimler, rated power 162/2300 , max. torque 850/1200-1600,the national V emission standards. Fuel tank capacity : 200L |

Operating mode |

Mechanical control |

|

|

Gearbox |

Mechanical transmission with synchronizer from Shanxi Gear, 6 forward gears and 2 reverse gear |

Main winch system |

Driven by a hydraulic motor, with built-in planetary gear reducer and constant closed brake fitted, Drum with Lebus-type grooving, non-rotating wire rope. |

|

|

Alxes |

2-axle chassis, 2nd axles for driving, 1st axle for steering, high strength load bearing axles designed by foreign advanced technology, with reliable performance. 1st axle: single tire, for steering; 2nd axle: double tire, for driving. |

Slewing system |

Single-row roller slewing ring with external teeth may continuously slew 3600 after being driven by single-slewing gear arranged at its right side. Each planetary gear slewing reducer is actuated by a hydraulic motor.Power control and free-sliding function are available, and speed may be infinitely regulated. |

|

|

Suspension |

Hydro-pneumatic suspension is adopted for all axles, providing good shock absorbing effect. Functions of automatic leveling, suspension lifting, elastic/rigid state switch-over, etc. are available. |

Elevating System |

Single-cylinderwith a self-compensating electronic- proportional control balance valve equipped. |

|

|

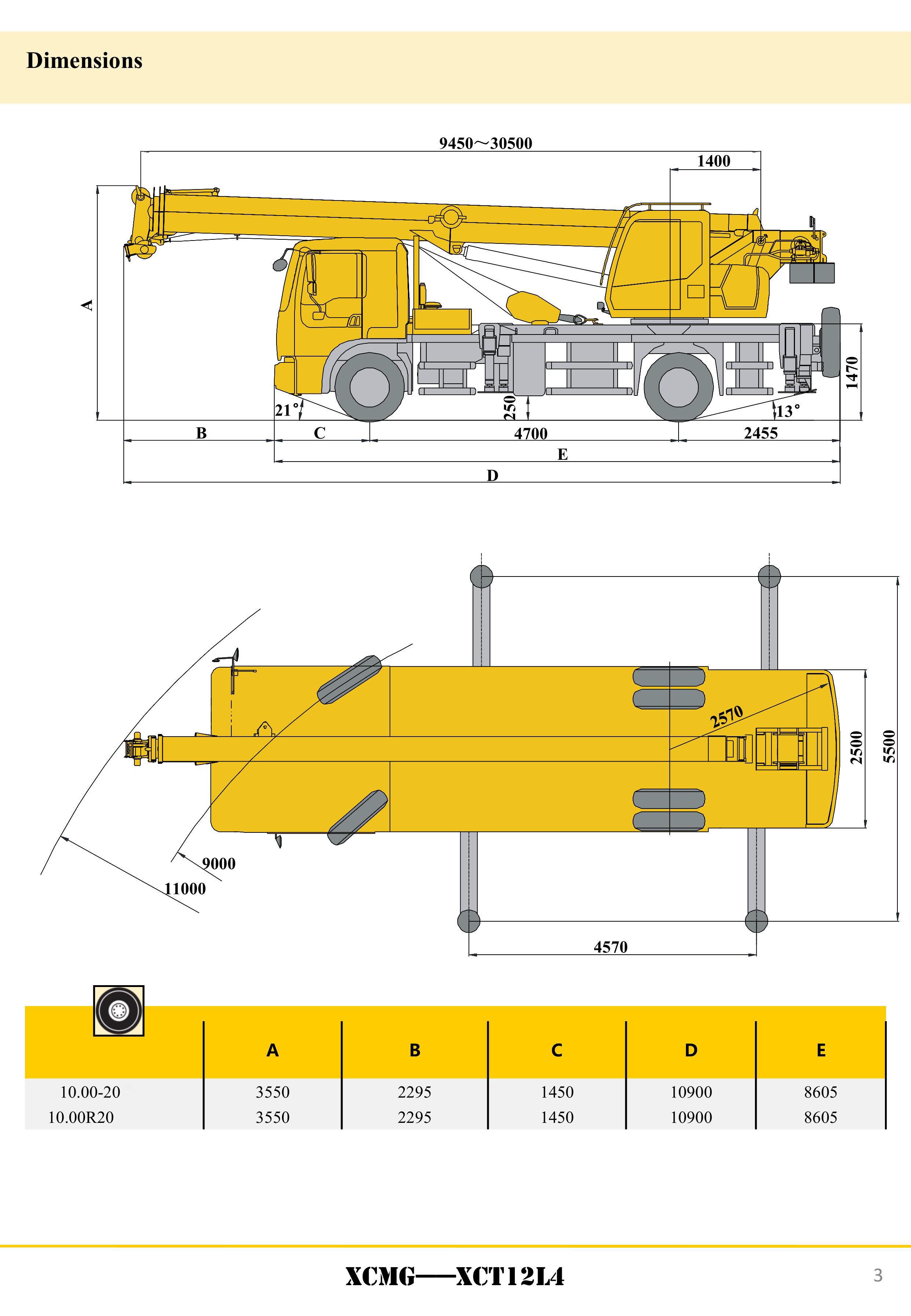

Tires |

10.00-20(Standard) 10.00R20 ( Optional) |

Operator\'s cab |

Ergonomic cab design, with swing-out doors, safety glass, sun visor, adjustable seatsand protective rails equipped. Fan is standard and air-conditioner is optional. |

|

|

Brakes |

Double circuit, air braking, drum brake. Service brake: double-circuit air pressure brake, acting on all wheels. Parking brake: spring energy brake. Auxiliary brake: engine retarded brake, engine exhaust brake, safe and reliable, which prolongs the service life of brake friction disc. |

Safety devices |

Hydraulic counterbalance valve; Hydraulic relief valve; Double-way hydraulic valve;LMI;Spring return system of control levers;Lowering limiter for preventing wire rope from over-releasing;Anti-two block at boom head for preventing wire rope from over-winding. |

|

|

Steering |

Mechanical steering system with hydraulic boost. |

Fixed counterweight |

Total weight of 0.9t. |

|

|

Driver\'s Cab |

Equipped with four-point connecting structure, the new full driver\'s cab of steel has open car doors on both sides. The main drivers can adjust height automatically. With double seats, the passenger\'s seats can be used as simple sleeper for temporary rest of drivers. Safe glass with electric lift contributes to good heat-proof effect. Automatically adjustable rearview mirror is safe and convenient. The steering wheel can adjust the height and angle, which is suitable for operators of different heights. LCD, bus control, centralized information show; and the layout of center console with new combination is safe and reasonable which adopts arc design and represents humanization. Fixed wiring harness connector save the space of driver\'s cab with fixed plug-in components. Integrated central distribution box enhances the reliability of electric system in driver\'s cab. The application of PLC control system improves the stability of chassis electric and the efficiency of error self-diagnosis. It is equipped with standard CD player and air-conditioner both for cooling and heating. |

Additional equipment |

||

|

Vice winch system |

Driven by a hydraulic motor, with built-in planetary gear reducer and constant closed brake fitted. Drum with Lebus-type grooving, non-rotating wire rope. |

|||

|

Fixed jib |

Lattice welding structure, with 0° jib offset angles available. Jib length7m. |

|||

|

Electric system |

24V DC, negative grounding, two 12V batteries inseries. Output voltage of generator is 28.5 ± 0.3 V output current is 70A. |

|||

|

|

|

|||

|

Boom system |

||||

|

Boom |

made of high strength steel. The single cylinder plus ropes system is used as telescoping system.Boom length8m〜25.5m |

Air conditioner |

air conditioner in Operator\'s cab is optional |

|

|

Single top |

Single pulley, fitted on boom head, used for single line operation.Its lifting performance is the same as that for boom, but could not exceed 2100Kg |

|||

|

Single top |

Single pulley, fitted on boom head, used forsingle line operation. Its lifting performance is the same as that for boom, but could not exceed 2100Kg. |

|||

|

Fixed jib |

Lattice welding structure, with 0° jib offset angles available. Jib length7m. |

|||

|

Product parts list is as mentioned above, please refer to the product quotation for specific parts. |

||||

|

XCMG—XCT12L4 |

||||

|

Weight |

||||||||

|

Axle |

1 |

2 |

Total weight |

|||||

|

t |

6 |

10 |

16 |

|||||

|

|

||||||||

|

Hook |

No. of lines |

Weight kg |

Dimension mm |

Remarks |

||||

|

12t |

6 |

145 |

1002x410x242 |

Single hook ,StandardStandard |

||||

|

2.1t |

1 |

60 |

518x236x236 |

Single hook ,OptionalStandard |

||||

|

|

||||||||

|

|

km/h |

|

||||||

|

10.00-20 |

2-90 |

41% |

||||||

|

Working speeds |

||||||||

|

Drive |

Working speed |

Max. single line pull |

Rope diameter/ length |

|||||

|

|

0-130 m/min, single line,4th layer |

23kN |

12mm/140 m |

|||||

|

|

0-3 r/min |

|||||||

|

|

Approx. 45s for boom elevation from -2° to 80° |

|||||||

|

|

Approx. 80s for boom extension from 9.45m to 30.5m |

|||||||

|

XCMG—XCT12L4 |

||||||||

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall