Product introduction

XCMG Official Telescoping Boom Crane SQ12SK3Q for sale

Inquiry

Basic Info.

View All >

Application

BrandName

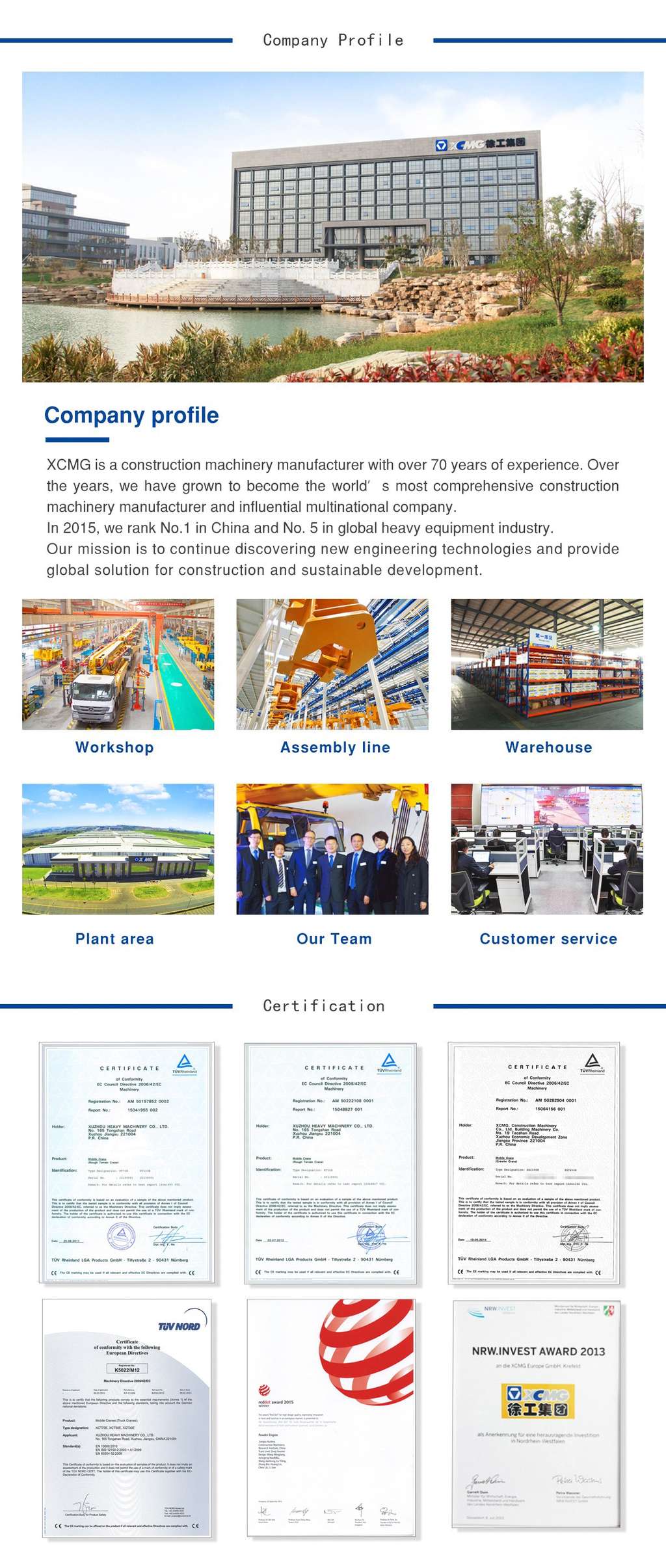

Certification

XCMG E-commerce Inc.

Certified for

8

years

5.0/5

Rating

Within 24 hours

Response Time

2017-12-31

Year of establishment

Company Adress:

C1c5, Software Park, Xuzhou, Jiangsu, China

Description

Recommendation

SQ12SK3Q Telescoping Boom Crane

1.Throttle Control System

Changing the form of previous manipulation and throttle operation

individually,Realization of the bilateral handle synchronous and driving throttle

acceleration and deceleration automatically, due to the speed change steady,it can easily to carry out the lifting work.

Maximum savings in preparation time before and after operation, to ensure

that customer’s vehicle could be in a driving state in the shortest time, and

prevent crane damage accident caused by hoist swing to enhance the safety of

driving.

3.Hoisting overwinder device

If a user is negligent or unfamiliar with the operation of lifting hooks,the hoisting

overwinder device will stop hook raise in time, to prevent the safety of

personal and property caused by fracture of wire rope.

Slewing locking device can ensure that the lifting arm does not sway

because of the centrifugal force during the driving and steering process of the

vehicle,to avoid all kinds of accidents caused by swaying.

The hydraulic system adopts dual high pressure gear pump, multi-way valve

hoisting joint to realize the converging, to improve the speed of winch, at the

same time, it can realize the compound action of crane.

6.Torque limiter

It can select torque limit

overload protection device to prevent users because of negligence or unfamiliar with the lifting

operation principle of overload operation, thereby causing the vehicle rollover

and crane damage accidents.

Application

BrandName

Certification

ModelNumber

SQ5SK3Q

Max.LiftingHeight

14.7m

Max.LiftingLoad

12000kg

PlaceofOrigin

China

RatedLiftingMoment

RatedLoadingCapacity

Span

2270-5270mm

cerBrandName

XCMG

modelname

TruckMountedCrane

Add to compare

Done

NaN% off

coupon

Get your coupon

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

Get more Coupons >

* Description

Or choose from these questions:

What is the best price you can offer?

Do you support customization?

What is the MOQ for this product?

Add Attachments

Add Attachments

Your information

* Mobile Phone

* Full Name

Send Inquiry

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall