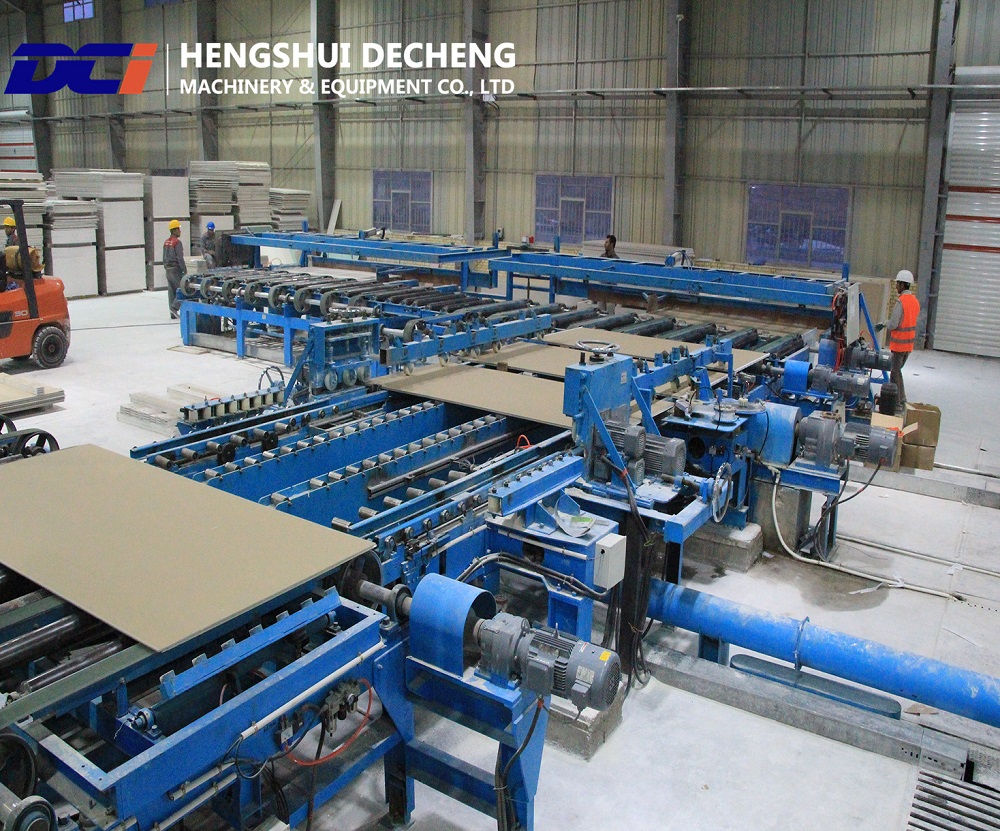

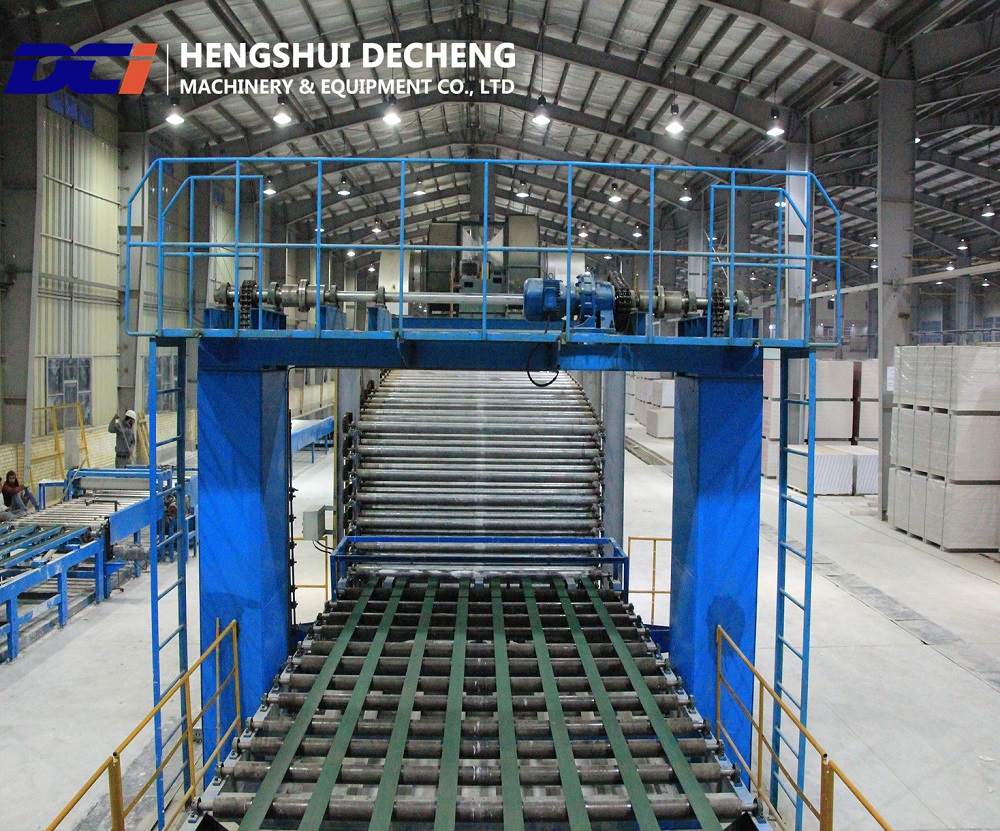

Gypsum Board Production Line/ Paper Faced Gypsum Board Machinery

Description

Recommendation

1. Annual output:

5million to 30 million sqm(based on thickness of 9.5mm gypsum board)

2. Working time: 24hours/day and 300 working days/year

3. Raw material: Gypsum powder, shielding paper, modified starch,

foaming agent, glue

4. Fuel: Natural gas, diesel, heavy oil or coal

5. Product quality and specification:

1) The product is in compliance with National Standard GB/T9775-2008

2) Product specification:

Length: 2400mm~3600mm

Width: 1200mm or 1220mm

Thickness: 8mm-20mm

6. Main process:

1)Raw material blending;

2)Shaping;

3)Wet board/panel conveying;

4)Drying;

5)Dry board/panel conveying;

6)Finished product stacking and storage.

7. Main

technology:

The production line adopts special designed hot air stove heating system

8.Raw material consumption list:

(Based on 9.5 mm gypsum board for reference)

|

Gypsum |

6.8kg/m2 |

|

Shielding paper |

0.48kg/m2 |

|

Modified starch |

0.035kg/m2 |

|

Foaming agent |

0.008kg/m2 |

|

Glue |

0.005kg/m2 |

|

Fiberglass |

0.025kg/m2 |

|

Electricity |

0.3kwh/m2 |

|

Water |

4.8kg/m2 |

|

Light oil |

1,000,000kcal/hour |

|

Natural gas |

0.45m³/m2 |

Till now, we\'ve manufactured and supplied complete sets of

machine lines to Russia, Oman, Uzbekistan,United Arab Emirates, Iran.

Payment

conditions:

30% (USD) prepaid by

T/T as down payment;

70% by irrevocable L/C at sight

a).65% shall be paid against shipping documents at sight.

b).5% shall be paid against performance guarantee at sight.

What\'s more , Kunlun bank account available to make convenient for Iranian

clients

Production

Method of Gypsum Board Production Line:

This production line

used the calcined gypsum powder, water and various additives are

automatically and separately measured and conveyed into the mixer by continuous

auto-conveying system. After well mixed into slurry and spreaded onto the

gypsum board protective paper which is continuously moving forward. During the

progressing process, the slurry is gradually dispersed with vibration, and

jointed with back protective paper. When going through extruded shaping

machine, the slurry is fully wrapped by upper and lower paper, pressing into

well-regulated flat board which is continuously brought forward as per a stable

and strictly controlled speed. After any minutes , the calcined gypsum in the

slurry is hydrated again and crystallized into tiny interpenetrative dihydrate

gypsum crystal with higher strength. And then, the wet gypsum board with a

certain strength and regular shape is precisely cut into individual boards with

set size by an auto-controlled cutting system. The individual boards are

orderly arranged, turned over by program control system and brought into the

dyer. In the dryer, the absorbed water in the boards is evaporated away.

following strict drying system(The crystal water in the gypsum crystal has no

loss). After brought out from the dryer, the boards are gradually cooled down

in the running process. The front sides of every two boards are folded after

turned over again, and the two ends are cut into boards with regular size and

nice appearance by end sawing machine. And finally the boards are

conveyed to automatic stacking machine and stacked into well-ordered finished

products before put into storage.

Labor

sanitation

Safety design

Safety design for factory area

The factory road

traffic design and outdoor fire hydrant arrangement will be in conformity with

every requirement in "Achitectural Design Fire Prevention Norm"; The

pavements and driveways are smooth, unblocked, and there are enough lighting facilities

at night; Set covers over the draniage ditches in the factory; Make it easy to

go through, discharge, convenient and safe; at the same time do virescence in

the whole factory to reduce the dust and noises.

Safety design for workshop

In the workshop, certain safe distance must be left for the main passages

and operating passages, between equipments and the building, between equipment

and equipment, and between equipment and passages; Set guard rail on all

workbench edges; Set covers over drainage ditches; Lighting is enough in the

workshop; All electrical equipments have ground protection, and there is

overhauling power of 36V to ensure of overhaul safety.

Harmful factor in producing:

Variety of harmful substance: Noises from fan, air compressor, etc.

Measures to reduce harmful factors: Do best to select low noise equipments to

reduce the noise from sound source, and meanwhile add anti-vibration soft

connectioner and muffler on the fan.

Precautionary measures of safety and sanitation

Protective appliances shall be allotted to each worker according to real

working conditions; All equipment is managed by certain person, the detailed

operational procedure shall be made. Workers on duty must carry on safety

education and corresponding skills training; strictly operate according to

operation procedure to ensure the person\'s security and equipment\'s good

condition; Regularly carry on safety education to staff; Regularly organize

safety inspecton to dispel the accident potential in time.

Explosionproof

Explosive materials are not produced and discharged in the production

workshop of this project. There is no factor of explosion.

Fire fighting system

Our equipment is not easy to produce fireworks, so don\'t need any corresponding

fire detection device.

After Sale Service

DCI is pleased to provide the parts,knowledge and expertise to assist with all

your plant\'s maintenance and upgrade needs.We can supply as below:

Spare Parts:

All Rollers and Shafts

Mixer Parts

Forming Plate Parts

Saw Blades

Forming Belts/Conveyor Belting

Carbon Bearings

Dryer Sprockets

Chain

Chain Guides

Head/Tail Pulleys

Plat Belt Drive Pulleys

Filter Bags

Raw Material

Modified Starch

Paper

Foaming Agent

Glue

Edge Tape

Fiberglass

White Tape

Technical Support

DCI\'s guarantee is within 1 year free after delivery and long-term service

DCI can help u to modify equipment and increase production capacity

DCI can help u solve any problems related to the gypsum equipment

DCI,the gypsum machinery expert,your best choice!

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall