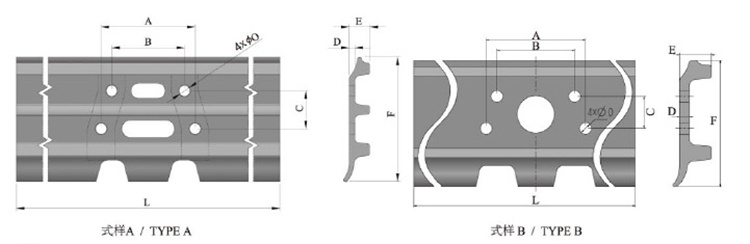

XCMG Manufacturer Excavator Accessory Steel Track Shoes for Crawler Excavator

Description

Recommendation

Product Highlights:

1. According to different main engine types and working conditions, the mud leakage holes of the track shoes are individually designed to reduce the damage of external hard objects to the track and improve the service life of the track shoes;

2. The overall spray pressure quenching heat treatment is adopted, the flatness control level of the product is better than that of domestic counterparts, the cross-section hardness is uniform, and it has excellent mechanical properties and good abrasion resistance;

3. The large-tonnage mine track shoe adopts the "double-tooth" and the two-end groove structure, which not only effectively improves the crawler grip, but also avoids the bolt loosening and fracture caused by the transverse extrusion of the track shoe when the whole machine turns.

uMore Excavator Accessory

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall