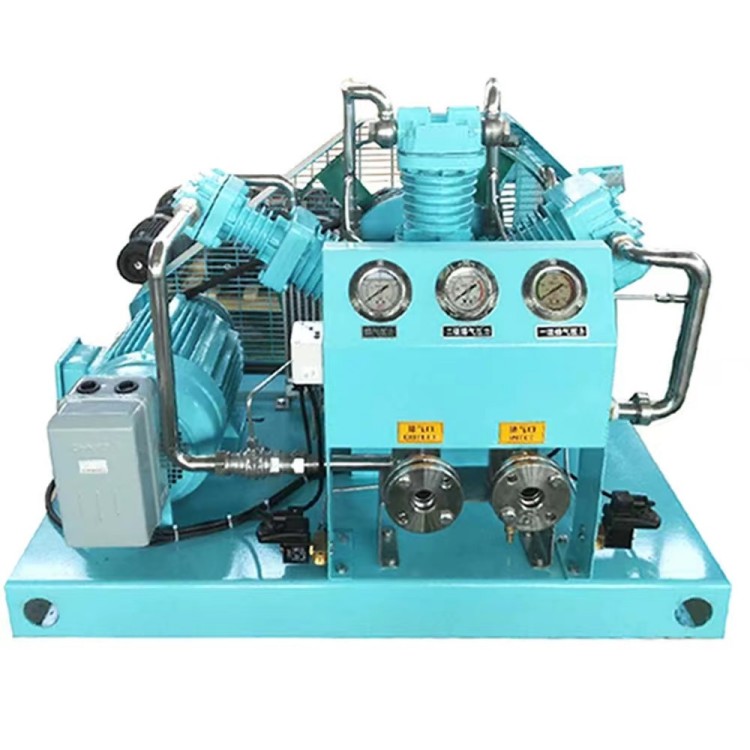

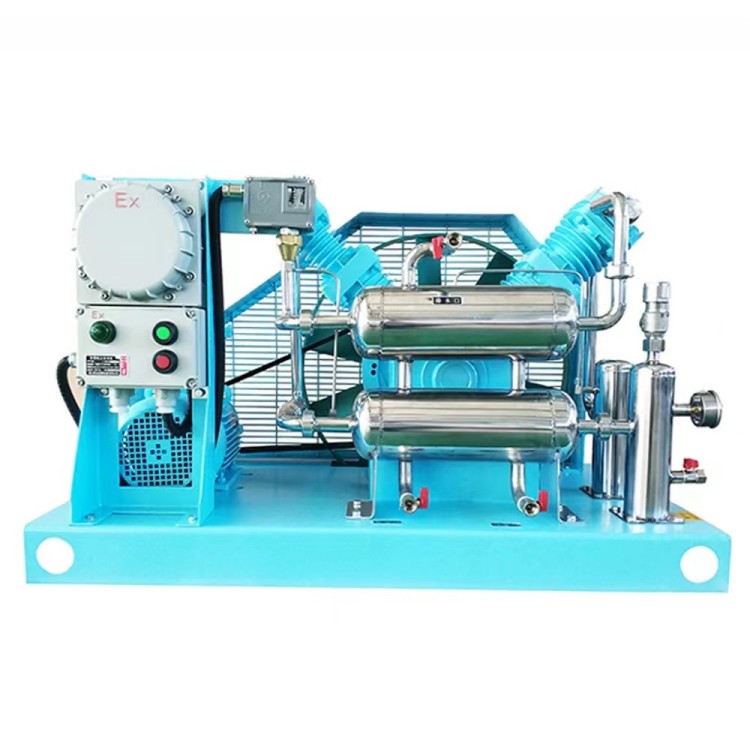

Auwin Energy - Nitrogen oil free supercharger

Description

Recommendation

The use and introduction of oil-free compressor

For the oil-free compressor every 2000h or so, in order to remove the dust on the heat exhaust surface, open the purge cover of the cooler in the fixing bracket of the centrifugal fan, and purge the cooler until the dust on the heat exhaust surface is cleaned. If the dirt on the heat discharge surface is serious and cannot be cleaned, remove the cooler, pour out the oil in the cooler and close the four international trade to prevent the waste from entering, then blow the dust on both sides with compressed air or clean with tap water, and dry the water stains on the surface. Put it back in place. Remember that! Do not use iron brush and other lumps to shave the waste material to prevent damage to the heat pipe surface. The moisture in the discharged condensed water air is likely to condense in the oil and gas separation tank, especially in humid weather, when the exhaust temperature is lower than the pressure of the vapor body leakage or standby cooling, there is a greater need for condensate to carry out precipitation. Oil containing too much water will cause the emulsion of lubricating oil, harm the safe operation of machinery and equipment, such as :1. 2. The expected effect of oil and gas separation is reduced, and the pressure difference of oil and gas separator is enlarged. Leading to corrosion of parts. Therefore, the condensate discharge schedule should be formulated according to the air relative humidity. Sewage treatment form of condensed water

It should be carried out after the machine and equipment are on standby, there is no pressure in the oil and gas separation tank, sufficient cooling, and sufficient condensate accumulation, such as before morning operation. (1) Screw out the front screw of the ball valve at the bottom of the oil and gas separation tank. ② Slowly open the ball valve sewage pipe, until the car oil is discharged, close the ball valve. Screw on the ball valve before the screw block.

- 1、Select the Clip Coupon button

- 2、Add 1 item from the products below to your Cart using the Add to Cart button or select See Options for specific product variations.

- 3、ITEMdetails.WhenyouredoneshoppingselectGotocart

* Description

Add Attachments

Add Attachments

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall