6.3-meter Super Large Diameter Drilling Successfully Concludes

The foundation of the main pier of the bridge adopts a total of 18 ultra-large diameter drilled piles with a diameter of 6.3 meters, which are currently the largest diameter drilled piles in China. The depth of the piles is 106 meters, with a water depth of 66 meters and a rock depth of 40 meters. Some of the piles reach a depth of 116 meters. The XCMG XR1600E rotary drilling rig needs to penetrate through layers of highly weathered granite, weakly weathered broken granite, fractured rock, and slightly weathered broken gneiss, among other complex formations, to lay the foundation for the bridge at the deep sea.

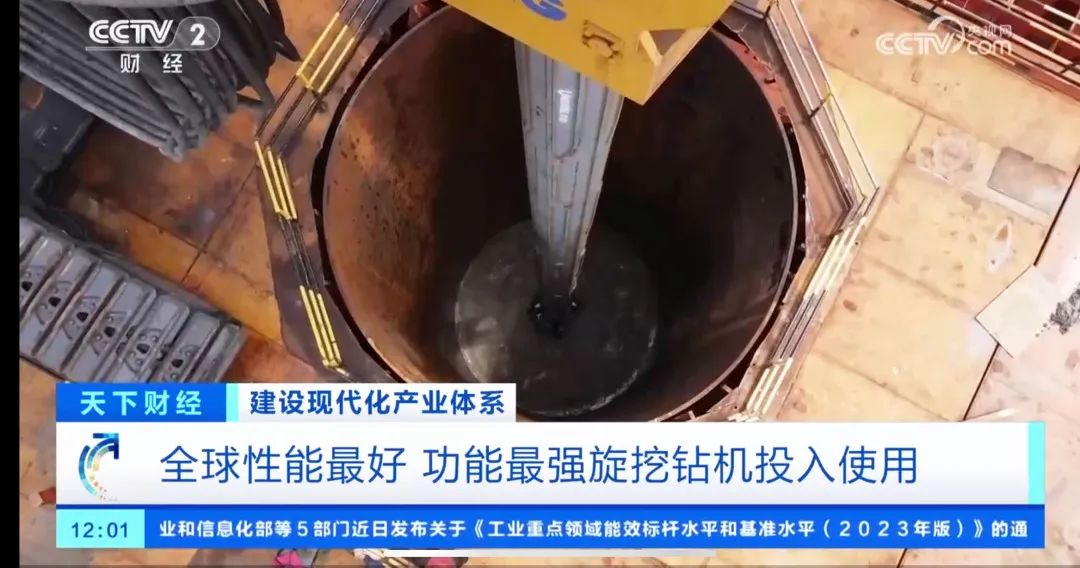

The construction platform where the XCMG XR1600E rotary drilling rig is located has relatively hard layers, and the seabed formation is inclined rock. The project team used roller cutter drill bits in four stages to ensure the verticality of the pile foundation. They also broke the conventional staged drilling process, reducing the number of stages and adopting a four-stage drilling process with diameters of 2 meters, 3 meters, 4.5 meters, and 6.3 meters, breaking through the 1.8-meter difference in staged drilling.

The XCMG XR1600E rotary drilling rig is currently the world's largest-tonnage rotary drilling rig, with a maximum drilling diameter of 7.5 meters and a maximum drilling depth of 190 meters. The equipment is designed in a modular manner, making assembly quick and transportation convenient, and it has stable performance.

The impressive performance of the XCMG XR1600E rotary drilling rig marks a new milestone in global foundation construction equipment, providing technical support for more super projects to transition from blueprints to reality.

Home

Home

Categories

Categories

Discover

Discover

My Machmall

My Machmall